Produk Beskrywing

Produk Aansoek:

Meubels, mediese toerusting, fiksheidstoerusting, olie-eksplorasie, vertoonrak, plaasmasjinerie, brug, bootvaart, struktuuronderdele.

Toepaslike tipe vir buis:

Spesiaal vir ronde, vierkantige, reghoekige, ovale, middellyf ronde buis en ander metaalpype

Toepaslike materiaal:

Koolstofstaal, vlekvrye staal, aluminium, koper, koper, gegalvaniseerde staal.

Outomatiese bondellaaier Staal vierkantige pypmaakmasjien | |||

Pyp tipe | rond, vierkantig, reghoekig, ovaal, OB-tipe, C-tipe, D-tipe, driehoek, ens (standaard), Hoekstaal, kanaalstaal, H-vorm staal, L-vorm staal, ens (opsie) | ||

Pyp lengte | 6000mm | ||

Pyp grootte | Φ20-200mm | ||

Herhaal posisie akkuraatheid | ± 0.03mm | ||

Posisie akkuraatheid | ± 0.05mm | ||

Vesel laser bron | 1000w/1200w/2000w/2500w/3000w | ||

Posisie spoed | Maksimum 90m/min | ||

Chuck roteer spoed | Maksimum 105r/min | ||

versnelling | 1,2g | ||

Sny versnelling | 1g | ||

Bundelgrootte | 800mm*800mm*6000mm | ||

Bondel gewig | Maksimum 2500 kg | ||

Elektriese kragtoevoer | AC380V 50/60Hz 3PH | ||

Belangrikste kenmerke

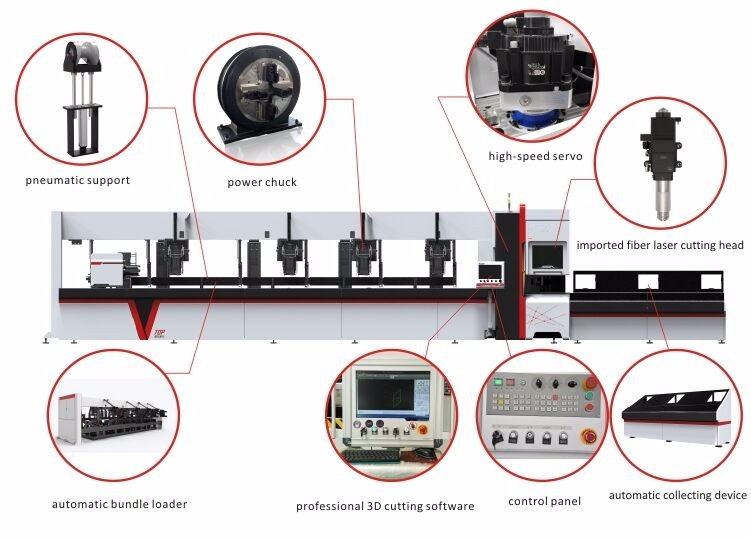

OUTOMATIESE BONDELLAAERSTELSEL

1, Ronde pyp, reghoekige pyp en ander pype kan ten volle outomaties gelaai word, sonder menslike ingryping. Ander vorms pyp kan semi-outomatiese voeding kunsmatig wees

2, Maksimum laaibundel 800x800mm

3, Maksimum laaibundel gewig 2500kg

4, Die totale voermanipuleerder met raam- en draadwydtebeheer vervoerskakels in 2200mm, totale hoogtebeheer in 2300mm, maksimum hoogte van nie meer as 2500mm nie. So oor die algemeen in houers

5, Die bandondersteuningsraam vir maklike verwydering

6, Voedende robotliggaam met 'n kettingvervoerbandstruktuur geïntegreerde ontwerp, maklik om te ontfout vervoer

7, Die pneumatiese stelsel komponente gebruik AirTAC of ander meer hoë-end handelsmerk, PLC beheer, sensors en ander geselekteerde Omron, Schneider en ander bekende handelsmerke. Verseker die stabiliteit van die stelsel en uitvoerstandaard

gedetailleerde

Masjienonderdele

Naam: Outomatiese laaimeganisme

1.Die totale voermanipuleerder met raam- en draadwydtebeheer vervoerskakels in 2200mm, totale hoogtebeheer in 2300mm, maksimum hoogte van nie meer as 2500mm nie. So oor die algemeen in houers

2. Voer robotliggaam met 'n kettingvervoerbandstruktuur geïntegreerde ontwerp, maklik om te ontfout vervoer

Masjienonderdele

Naam: outomatiese versamelapparaat

1. Outomatiese opheffing, ontvang buis en skroot in die mandjie

2.Visuele skaalsteun kan die steundiameter vinnig aanpas volgens die pypdiameter

3.Visuele skaalverstelbare ondersteuningshyser bespaar voer tyd, verseker konsentrisiteit, voorkom dat die pyp swaai

Belangrikste kenmerke

Naam: Power chuck

1. Chuck deur die gaspaadjie te verander, die gewone vierkaak chuck-skakel, optimalisering Cheng-slag power chuck dubbelwerkend.

2. Sny verskillende diameters, die vorm van die pyp in die reisbereik (bilaterale slag 80 mm), hoef nie die kakebeen maklik opgestel en gesentreer te word nie.

3. Maklike omskakeling van verskillende diameters, 'n aansienlike besparing van opsteltyd.

Masjienonderdele

Naam: Pneumatiese ondersteuning

Die sny van pype van verskillende deursnee, deur verstelbare ondersteuningstelsel om vinnig en akkuraat konsentrisiteitspyp en kloue te vind, om vinnige voeding te bereik, sorg vir voerdoeleindes, spaar opsteltyd wat uitsny. Jy kan chuck-ondersteuning help, die swaaipyp verminder.

Belangrikste kenmerke

Naam: Integrasiebed

1.As 'n hele plaat gelaste bed, die hele lengte van 8 meter.

2.Integrasiebed kan beter konsentrisiteit van toerusting verseker, vertikale, presisie-installasie vinnig en doeltreffend.

3.Die hele struktuur is kompakte presisie

Vinnige besonderhede

Toestand: nuut

Lasertipe: vesellaser

Toepaslike materiaal: metaal

Snydikte: Hang af van kragbron

Snyarea: buislengte 6m,8m; buis deursnee 20-300mm

Snyspoed: afhangende van materiaal en veselkrag

CNC of nie: Ja

Afkoelmodus: Waterverkoeling

Beheer sagteware: Cypcut

Ondersteunde grafiese formaat: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Plek van herkoms: Anhui, China (vasteland)

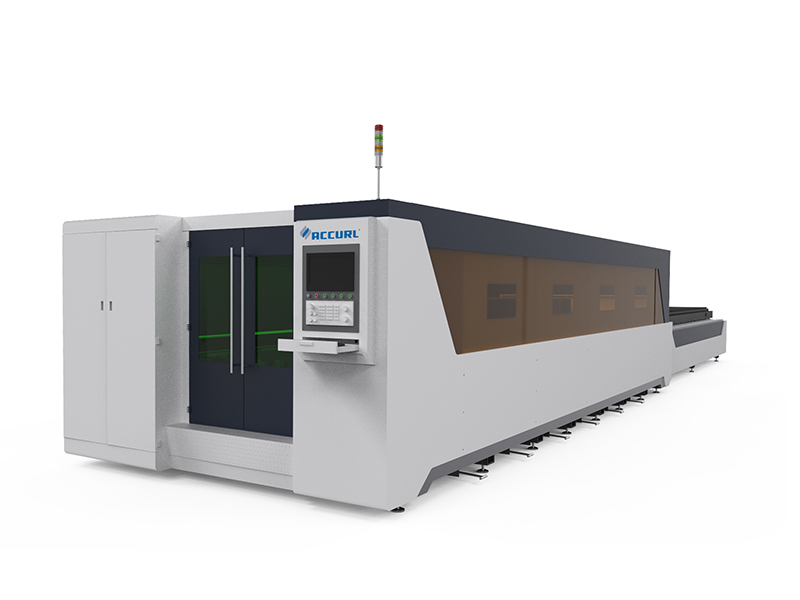

Handelsnaam: ACCURL

Sertifisering: CE

Na-verkope diens gelewer: Ingenieurs beskikbaar vir masjinerie in die buiteland

Model: P2060A

Herhaal posisie akkuraatheid: ±0.03mm

Posisie akkuraatheid: ±0.05mm

Vesellaserbron: 1000w/1200w/2000w/2500w/3000w

Posisiespoed: Maksimum 90m/min

Versnelling: 1,2g

Elektriese kragtoevoer: AC380V 50/60Hz 3PH